Choosing a chainsaw using power to weight ratio

Choosing a chainsaw can be a complicated process. The size of the saw you purchase will have a major impact on what you can accomplish, but bigger isn’t always better. Adding to the confusion, there are very few universal specifications used by all manufacturers to make comparisons easy. So where do you begin? I generally start with two factors when beginning the selection process. The chainsaw’s maximum recommended bar length to narrow down the selection, and the chainsaw’s power-to-weight ratio to compare individual models.

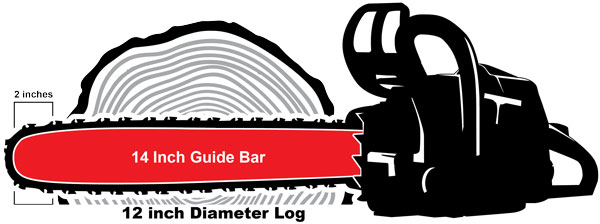

Maximum recommended bar length: The longest bar length recommended by the manufacturer for a particular chainsaw model. Most manufacturers will provide a range of lengths that are compatible with each saw in their specifications documentation.

Power to weight ratio: Calculated by dividing a chainsaw’s power (hp or KW) by its weight (lbs or kg). Typical calculations use the dry weight (no gas or bar oil) of just the chainsaw’s powerhead and exclude the weight of the bar and chain as they are generally a constant when comparing similar models.

Power (hp or kW) / Weight (lbs or kg) = Power to Weight Ratio

Narrowing down choices using the maximum recommended bar length.

To zero in on the chainsaw models appropriate for your consideration, ask yourself what is the typical diameter/thickness of the material you will be cutting most often? It is recommended that your bar length should be about 2 inches longer than the materials you are cutting to help prevent kickback and ensure you have enough power to make the cut in a variety of wood types (hard or softwood). Material with a diameter larger than the bar length can be cut with two passes from opposite directions but is inefficient and not recommended for frequent cuts.

Narrowing down your chainsaw selection by bar length will help keep you in the best range of saw sizes for your most common tasks. Big saws are fun to brag about, but they cost more and more importantly cause unnecessary fatigue which can lead to an accident. “Right-sizing” your saw especially for first-time buyers is an important safety consideration.

Running the numbers: compare chainsaws using power-to-weight ratios

Once you have narrowed the field down to a few options it is time to compare their specifications. Assuming you are comparing saws with similar build qualities, divide the powerhead’s stated power output (hp or kw) by dry weight to calculate each saw’s power-to-weight ratio. Displacement (cc or cu in) can be an indicator of a saw’s potential power, but horsepower or kilowatts is a much more reliable measurement of the actual power output of a saw. Once you have made the calculations look for the top three saws with the most power per pound or kilograms. These are the saws you want to consider in-person to make a final decision.

Note: Some manufacturers will state the gas and bar oil reservoir capacities. If there is a big difference in capacity between your final three, then consider recalculating using their wet weight (incorporating the bar oil and gas) into the calculation. Larger capacities offer longer run times, but even a few ounces will add up over a short time so it is good to be aware of it.

Why is the power-to-weight ratio important?

When people get tired they get complacent and sloppy, taking shortcuts and risks to finish the job as soon as possible. This is when bad things happen to even the most responsible people. Reducing the weight of your chainsaw is not a guarantee that you won’t have an accident, but using a saw that is too big for the task at hand for extended periods of time will definitely increase your chances of getting hurt. Ounces add up over time.

Exceptions – sometimes the heaver chainsaw is better.

Ideally, a chainsaw should cut the wood under its own weight (unless you are felling) using gravity to engage the cutters and move the saw through the wood. The operator is just there to guide it and control the throttle. Bucking logs or cutting rounds using a bucking horse is a situation where a heavier saw can reduce user fatigue by letting the saw do most of the work.

Using a sawbuck to position the logs at waist level, the operator can guide the saw through the wood. If the saw is too light, the operator will need to push down on the saw to move it through the log, increasing the amount of effort it takes to make each cut.

Pro Tips:

- There isn’t one saw that can do everything.

- Lighter saws are preferable when working in the woods or general cutting tasks

- Shorter runtimes can be beneficial, allowing for more breaks

- When tired, never make just one more cut, It isn’t worth it!