The drive sprocket is possibly the most overlooked part of a chainsaw’s cutting system. Although it could be considered the hardest working wear point after the chain, it rarely gets the attention it deserves. Quite literally, the drive sprocket’s job is to transfer all the momentum and torque from the chainsaw’s engine directly to the cutting chain.

Replace a chainsaw drive sprocket after wearing out two chains or if it is damaged. If you use multiple chains in a cutting session instead of re-sharpening a single chain, replace the sprocket when replacing the bar. Sprockets prematurely worn or damaged by improper use, frequent chain derailments, or the use of damaged or miss-sized chains should be replaced immediately to prevent damage to other components like the chain’s driver links and the bar’s rail groove.

Check the drive sprocket for wear as part of your pre-start procedure and chain sharpening routine. On a stopped saw, manually rotate the chain around the bar several times to feel for any binding, clunking, or slipping. The chain should move smoothly with little effort. When flipping the bar look at the sprocket for damage or excessive wear.

Why Is Replacing Your Drive Sprocket Important?

- A drive sprocket’s pitch changes as it wears. Over time this will cause loss of power and excessive wear on the chain and bar.

- Severely worn sprockets will make tensioning the chain harder, causing more frequent chain derailments. On a larger saw “throwing a chain” can bend chain links, ruining even a brand new chain.

- Generally speaking, it is quicker and cheaper to replace the drive sprocket than to fix the damage a worn one can cause.

Signs That Your Drive Sprocket Has Worn Out

If you prefer to use several chains out in the field rather than sharpening one chain continuously until it is worn out, you will need to inspect the drive sprocket more critically. I like to use multiple chains as it promotes flipping the bar on a regular basis, but obviously, it takes much longer to wear through a batch of chains. Because of this, I change my drive sprocket whenever I replace my bar.

Visual signs of sprocket wear:

Spur sprocket:

- Teeth should be smooth and consistent. If the teeth have become chipped it is time to replace.

- Excessively deep grooves caused by the chain’s driver links. See example. Some scoring is normal, but a deep groove is not.

- The chain has become is too long and will no longer tension correctly

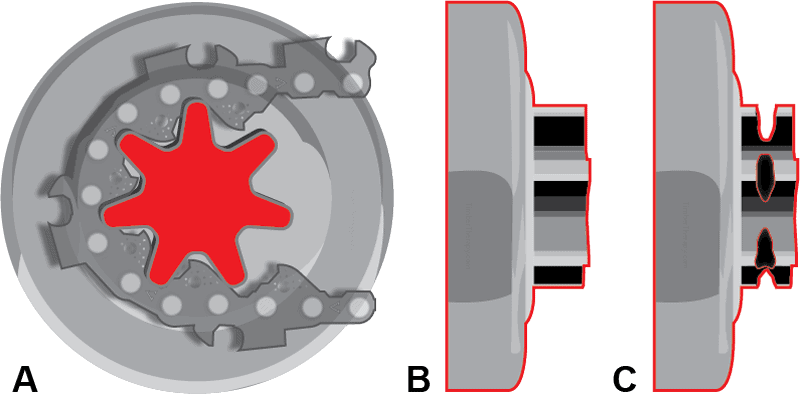

Spur Sprocket Diagram

Figure C shows a heavily worn spur sprocket that should be replaced

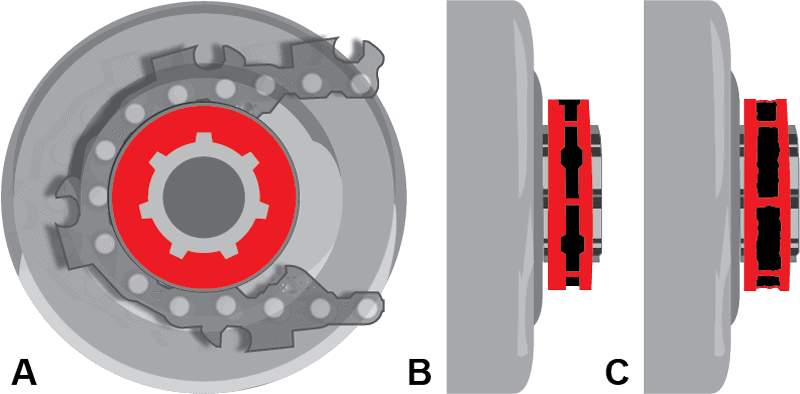

Rim Sprocket Diagram

Figure C shows a heavily worn rim sprocket that should be replaced

Rim sprocket:

- Channels should not exceed the wear indicators. Similar to cutters on a chain, rim sprockets have wear indicators on the left and right sides of each channel to indicate when to replace them.

- The sprocket should be symmetrical without warping side to side.

Tactile signs for Both Sprocket types:

- The chain feels like it is slipping or skipping under load

- Gradual loss of torque

- Increased vibration while cutting

- Frequent chain derailments

When it is time to replace your chainsaw’s sprocket there are a few additional items you might consider.

Types Of Chainsaw Drive Sprockets

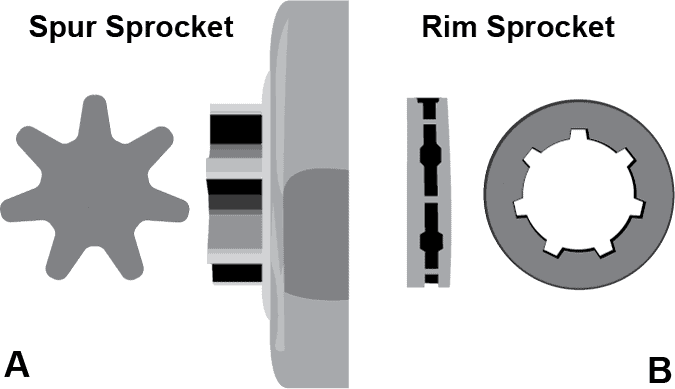

There are two types of chainsaw drive sprockets in a variety of gauges, pitches, and tooth configurations (6, 7, or 8) to accommodate different chains, bars, and performance needs. Your chainsaw will come from the manufacturer with either a spur or rim sprocket that works with the rest of your cutting components.

- Spur Sprocket: an open, star-shaped sprocket that is integrated into the clutch drum to create one rotating part.

- Rim (floating) Sprocket: a closed, channel sprocket that slips over a splined hub on the clutch drum, remaining free-floating.

Figure B: Rim Sprocket is a stand-alone part that slips over a sprocket on the clutch cover

Spur vs. Rim Sprocket – Is One Better?

Both rim and spur sprocket types do their job very well, but there are maintenance and performance differences to consider when changing your drive sprocket style. Spur sprockets are more durable, but rim sprockets are easier to replace and provide a slight increase in performance. In arborist and logger circles, many of these subtle differences are heavily debated. Think Ford vs. Chevy, Stihl vs. Husqvarna, Coke vs. Pepsi. However, there is agreement that you shouldn’t consider switching your sprocket type until your current sprocket is worn out. The benefits are not worth the cost of replacing a functional sprocket. Read my opinion on which drive sprocket is best

What to Consider When Replacing or Switching A Drive Sprocket

If you decide to change your drive sprocket type, the new sprocket must be compatible with the chainsaw’s chain and bar’s pitch and gauge. Additionally, you will need to ensure the new clutch drum is compatible with your brand of saw. Just like bars and chains, pitch and gauge must match. Getting it wrong can cause serious damage to the other cutting system components. Check out our chainsaw cutting system components article for more information on getting it right.

Should You Changing Your Sprocket’s Tooth Count

Chainsaw drive sprockets most commonly come in 6, 7, or 8 tooth variations. Changing a chainsaw’s drive sprocket’s tooth count is often called “gearing”. Changing your chainsaw’s gearing will change the cutting characteristics of your saw. More teeth will increase chain speed while fewer teeth will increase torque. The pros and cons are very similar to changing gears on a bicycle. First gear provides a lot of power to get up hills easily but is very slow on the flats. 10th gear is fast on the flats, but impossible to power up hills. Check out our drive sprocket speed calculator to see the difference.

Unless you are a professional or have very specific cutting needs, it is best to stick with the tooth count that came from the factory. Or at the very least, talk with your local dealer to see which sprocket tooth count is right for your needs.

Pro Tips

- If your chainsaw uses a rim-type drive sprocket, add a spare sprocket and retaining clip to your field service kit. There is nothing worse than being out in the woods. Miles away from civilization and your saw is out of service because one tiny, but important part failed.

- If your chainsaw uses a spur-type drive sprocket you can add a spare to your field service kit, but the fix isn’t so easy in the field.