What is the best sprocket tooth count for my Chainsaw?

Changing the number of teeth on your chainsaw’s drive sprocket to optimize performance is called gearing. More of an art than a science, gearing essentially changes the drive sprocket diameter by adding or removing teeth. Geering can be done on both spur and rim type sprockets but is easier on a rim sprocket due to their modular nature.

Unless you have very specific cutting needs, it is best to stick with the drive sprocket tooth count that came on your saw from the factory. The default tooth count will offer the most versatile combination of speed and torque under varying conditions.

How to calculate the chain speed of different drive sprocket tooth counts.

(((Chain pitch x 2) x number of teeth) x RPM) / 12 = chain speed in feet per secondOk, so you want to tinker with tooth count

Gearing is essentially slowing down or speeding up your chainsaw’s chain in order to increase cutting power or speed. Just like the gears on a bicycle or your car, there is a balance that needs to be maintained for optimal performance. Not enough torque and your engine will stall, too much and it will feel sluggish. Finding the sweet spot will take some trial and error, so it is always a good idea to talk with a professional in your area to see what they recommend.

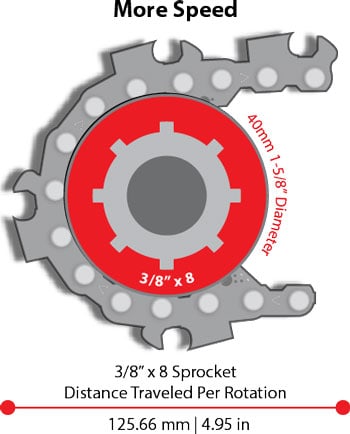

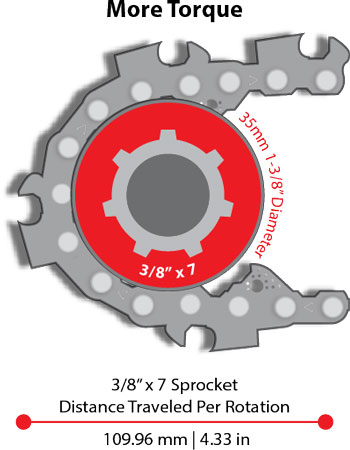

Sprocket size is shown: chain pitch “by” the number of teeth. For example, 3/8″ x 7 references a sprocket that is 3/8″ pitch with 7 teeth.

Need for Speed

If you live out west and/or cut a lot of softwood like pine then speed is what you’re after. To increase the speed of the chain, increase the drive sprocket’s diameter. Generally, one step up in tooth count (6 to a 7) or (7 to 8). The larger diameter increases the outer speed of the sprocket increasing the chain speed. Sounds simple, but other factors may need to be addressed such as chain gauge and bar length. Increasing the diameter/speed of the drive sprocket will reduce its applied power. At some point, depending on the horsepower of the chainsaw’s powerhead, it may no longer be able to rotate a heavy chain around a very long bar efficiently or at all.

8 tooth sprockets were originally developed to be used by loggers with a full skip chain to offset the impact of ⅓ fewer cutting teeth than a standard chain. Fewer cutters allow for more efficient chip removal but cut slower. The increased speed of the 8 tooth sprocket effectively made up the difference.

Increasing chain speed requires increased lubrication. When changing to an 8 tooth sprocket, set the saw’s oiler flow rate to max.

I Want Muscle

If you cut lots of hardwood, like oak and maple, or need to use a longer bar, then increased torque is what you need. To increase torque, decrease the drive sprocket’s diameter. Generally, one step down in tooth count (7 to a 6) or (8 to 7). The smaller diameter decreases the outer speed of the sprocket increasing the applied power on the chain. Think first gear on a bicycle. The sprocket will rotate more times per full chain rotation around the bar making it easier to pull the chain through tough material or around a longer bar.

Keep in mind that the entire cutting group needs to be taken into account when gearing your chainsaw. Bar length and chain gauge have a big role in whether changing the sprocket will be a success or a failure. The chart below is a very general guide to get you started but is in no way complete or definitive.

Common Chainsaw Bar and Sprocket Setups

Please note that modifying your chainsaw has risks and should only be done by experienced individuals. These setups are just a starting point and should be treated as such.

| Powerhead Size | Bar Length | Guage | # Teeth | Notes |

|---|---|---|---|---|

| 65cc to 80cc | 20” or less | 3/8 | 7 | Well balanced |

| 8 | Best with full skip chain | |||

| 32” or less | 3/8 | 7 | ||

| 8 | Performance Suffers in hardwoods | |||

| 85cc to 100cc | Up to 32” | 3/8 | 8 | Good speed and power |

| .404 | 7 | Good speed and power | ||

| 36” | 3/8 | 7 | Power | |

| 8 | Speed | |||

| .404 | 7 | Performance Suffers, too much chain drag | ||

| 8 | Not Recommended | |||

| 42” | 3/8 | 7 | ||

| .404 | 7 | Not Recommended | ||

| Over 100cc | 3/8 | 8 | Performance Suffers | |

| .404 | 7 |

Is there a 9 tooth sprocket?

Yes, there is a 9 tooth sprocket, but it is used in very specialized situations and requires a special bar profile to decrease the risk of chain derailment.

Does changing my sprocket tooth count increase wear on my chainsaw?

Changing the drive sprocket tooth count on your chainsaw will change its performance characteristics. Additionally, the change in sprocket diameter will change the tolerances between the bar and chain, especially when moving up a size. This can cause increased wear on the bar, chain, and clutch assembly. Make sure to size your components to work together to minimize wear as well as the risk of a chain derailment or injury.

Does a chain’s pitch have an effect on gearing?

Yes, the pitch of the chain has a direct effect on the drive sprocket’s diameter. A ⅜ pitch eight tooth sprocket has a very similar diameter to a .404 pitch 7 tooth sprocket. Many professionals use these two combinations on their chainsaws to maintain consistent gearing between them.

Pro Tips

- Make sure your bar chain and drive sprocket are all the same gauge and pitch.

- Lubrication is important. A faster chain requires more lubrication. Don’t forget to adjust the oiler.

- Most of the time going from a 7 tooth to an 8 tooth sprocket is no better or worse when using a standard chain.

- If it feels off, then it probably is. Running it harder or longer won’t fix the problem.